Ultrasound is gaining interest in the food industry due to its potential to improve processes based in mass and energy transfer. This document summarises its use for improving the drying, freezing and thawing of food.

Ultrasonic technology consists of the application of mechanical waves with a frequency over the threshold of human hearing (>16 kHz). In the food industry, high-power ultrasound (>1 W/cm2) is the one of great interest due to its possibilities. The effects of the application of high-power ultrasound in food products are dependent on the medium of propagation (liquid, solid or gas) and also the parameters of the process such as ultrasound frequency and intensity, among others.

Applying ultrasound in a liquid medium is the simplest and the most common process in the food industry producing the cavitation effect in the liquid and microvibrations (microstreaming) in the product resulting in the improvement of mass and/or energy transfer. This can occur in the US-assisted freezing and/or thawing processes. In these processes, the food can be unpacked or vacuum packed and submerged in water or in a liquid-based medium, mainly using an ultrasound water bath.

US and freezing

Freezing is a critical process since low freezing rates damage tissular cells of the food and lead to water leakage after defrosting, producing the loss of food quality. Due to this, high freezing rates are preferred. Ultrasound-assisted freezing has been shown to reduce the freezing time by around 30-40% by mainly shortening the water-ice crystal transition phase. This effect would mimic the lower impact in the food quality of the freezing process when high freezing rates are used. For example, the cooking loss (% of loss water after cooking the product) values of common carp (Cyprinus carpio) were similar to those of the fresh product: 7.9% in the fresh product vs. 8.3% when ultrasound was applied.

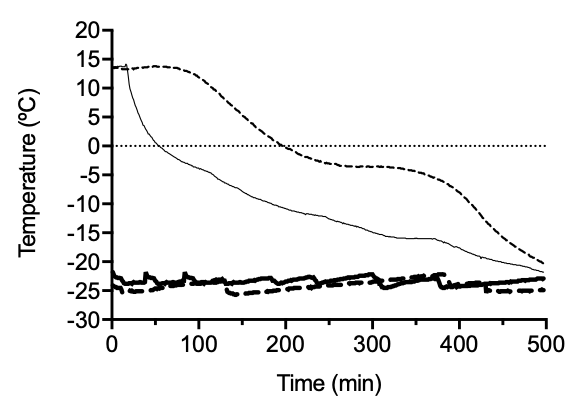

The above figure shows the freezing curves of 2 cm × 2 cm cylinders of meat sausages frozen in an ultrasound bath at −22°C by applying or not applying ultrasound (40 kHz, 50 W/kg). As can be observed, the application of ultrasound reduced the freezing time and even eliminated the water-ice crystal transition phase.

This process has been evaluated in different foods: panaria dough, potatoes, broccoli, apples, mushrooms, and pork loin.

For this application, a TRL (Technology readiness level) of 6 is assumed.

US and thawing

This process must be carried out as quickly as possible to avoid affecting the hygienic quality of the product, however bearing in mind that the higher the speed, the worse the sensory characteristics of the final product because time is required for the cells to reabsorb the released water during freezing.

Thawing time is reduced by using US. The thawing rate is influenced by the intensity of ultrasound treatment: the higher the ultrasonic intensity, the shorter the thawing time.

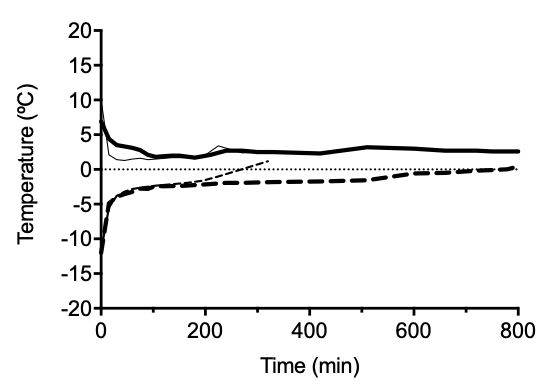

In the example above, a 65% time reduction to achieve 0ºC was described in cod fillets thawed by US (25 kHz; 15 W/kg). In this case, the water holding capacity and cook loss of the fresh product was maintained. Also, a better sensorial quality than the air defrosted product was observed.

This process has been evaluated in different foods: beef, pork, codfish, and tuna.

For this application, a TRL of 6 is assumed.

The application of high-intensity ultrasound in a gas medium (air), which is called airborne ultrasound, is more complicated than in liquid. In this case, the vibration generated by the ultrasound system is transferred to a radiator, which vibrates, transmitting the ultrasonic waves to the air. The product is located some centimetres far from this radiator, usually unpacked.

One of the main applications of airborne ultrasound is for the dehydration of foods.

US and drying/dehydration

Currently, one of the most widespread techniques in the food industry is air convection dehydration. It consists of removing a large part of the water from the food to improve the stability of the product, reducing its volume and weight and facilitating the handling and transport of the products. However, it is an energetically costly operation and, in some cases, requires long periods of time.

The application of US while drying improves the water removal process mainly by the phenomenon known as “sponge effect”, which enhances the diffusion of water from the interior of the product to the surface, accelerating the drying time. Drying time reductions by 20–30% have been described.

This application has been mainly tested at a lab scale in vegetables. A TRL of 4 is assumed.

| Title | Author(s) | Year | |

|---|---|---|---|

| Ultrasound in Food Processing: Recent Advances | Villamiel, M.; García-Pérez, J.V.; Montilla, A.; Carcel, J.A.; Benedito, J. | 2017 | Go to publication |

| Application of High-Power Ultrasound in the Food Industry | Leire Astráin-Redín, Salomé Ciudad-Hidalgo, Javier Raso, Santiago Condón, Guillermo Cebrián and Ignacio Álvarez | 2019 | Go to publication |

What is TRL?

TRL means "Technology readiness level".

TRL is rated on a scale from 1 (immature) to 9 (mature).