Microbial inactivation/decontamination by ultrasound has been, by far, the most studied application of this technology.

Two major phenomena determine the ability of ultrasound to improve food safety and extend its shelf life: its ability to detach microbial cells from food and surfaces in contact with food (knives, tables, equipment and belts) and to break microbial membranes leading to microbial inactivation.

Microbial decontamination and surface cleaning

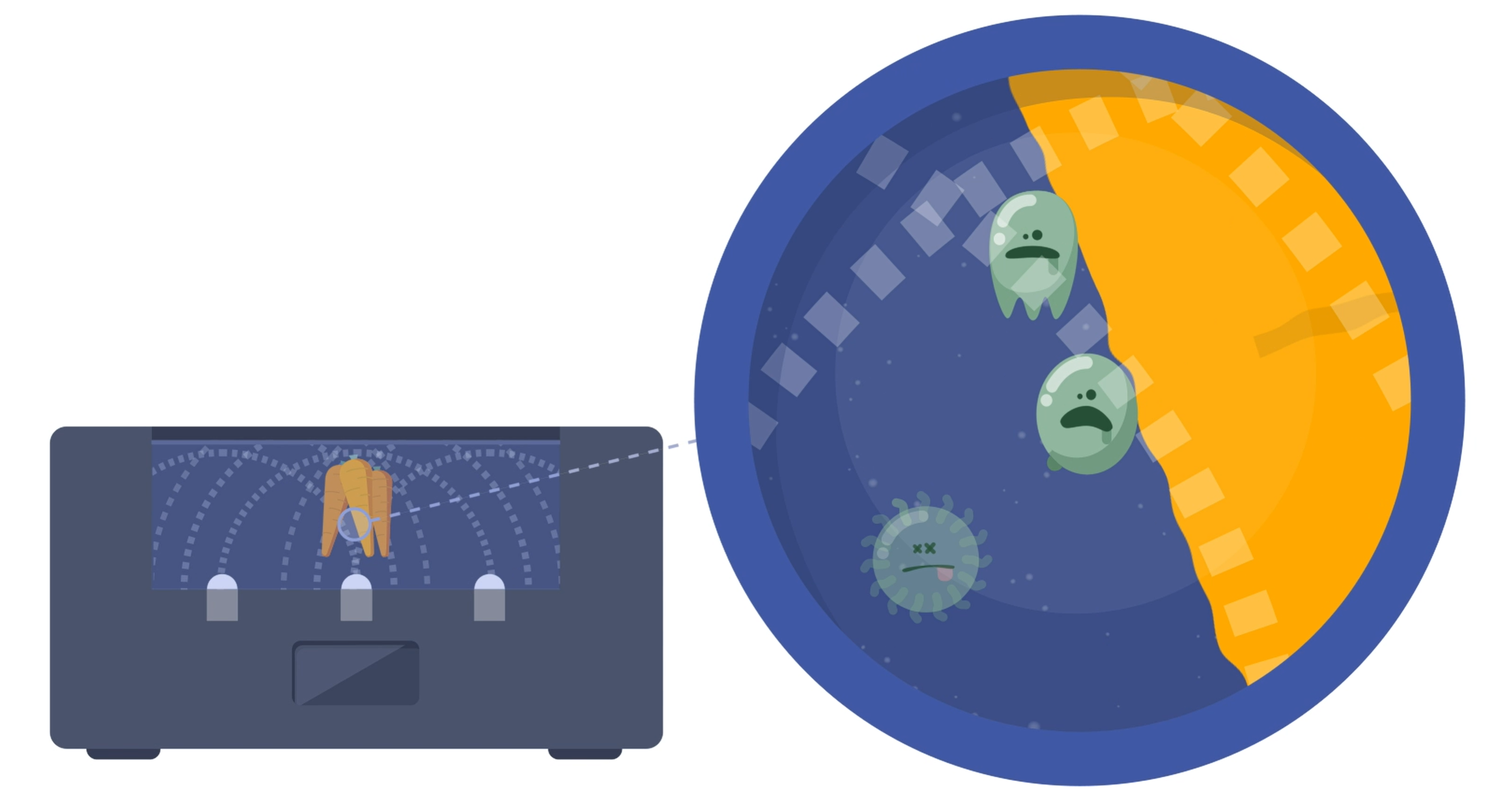

The cleaning and decontamination of food equipment and/or surfaces in contact with food are among the first applications of ultrasound in the food industry. For this purpose foods, belts or tools are submerged within a bath/pipeline in which US is applied and, as a consequence of cavitation, microorganisms adhered to them are released to the liquid. Thus, this application is mainly based on the ability of ultrasound to detach cells/break aggregates.

Pros

In fact, one of the major advantages of using this technology is that ultrasound is capable of accessing the irregularities and pores of food products and food processing surfaces, which usually limit the cleaning effectivity of traditional systems. In addition, they can also facilitate the access of chemical agents to microorganisms, and therefore increase its lethality, because of their ability to release and fractionate particles and even microbial biofilms, while reducing the amount of sanitizers/preservatives in the products, as well as in the wastewater.

The use of ultrasound for cleaning surfaces is a well-established technique for cleaning surfaces in several industries and even for household applications such as jewellery cleaning or skin scrubbers. Regarding the food industry, this technology is ready to be implemented (TRL-9) for this application on the industrial scale, and there are many providers in the market. It also has some other advantages, as compared to other emerging technologies, such as its easy implementability within most food processing lines and that it has a low equipment and operation cost.

From all the above described it can be concluded that ultrasonic baths can be successfully used to clean and decontaminate the surfaces of products such as vegetables, fruit, eggs, fish, etc.

Cons

However, one of the major limitations of this technology is that, when used alone, and in the best scenario, a microbial inactivation of around 1 Log10 cycle (90% reduction of the microbial population) could be achieved. The impact of this reduction on food safety and shelf-life will also depend on the product, initial contamination and storage conditions but will be, inevitably, limited.

Nevertheless, the efficacy of these ultrasound assisted decontamination processes is highly increased if they are combined with other technologies such as water-vapour steam or chemical agents such as acids, antimicrobials and disinfectants. The latter include, among others, sorbates and benzoates, cinnamon, vanillin, lisozyme, citral, sodium hypochlorite, chlorine, and chlorine dioxide. These combinations can lead to several log cycles of inactivation and would, therefore, substantially increase the shelf-life and safety of food products.

Links

Reviews about the potential use of ultrasound for the decontamination of meat, vegetables and surfaces and examples of currently available equipment for US assisted decontamination of food products and food contact surfaces:

Cleaning of conveyor belts using US

Combination of US and water-vapour systems for food decontamination

Pasteurisation and sterilisation of food products using US

Pasterurisation and sterilisation of food products requires microbial inactivation and, therefore, this application of ultrasound is based on its ability to disrupt microbial envelopes. However, despite the improvement of the current ultrasound generators, most published data indicate that the germ-killing efficacy of ultrasound is still relatively low under room conditions, and, therefore it should be combined with other technologies/agents to achieve these objectives. Combinations tested to date include its combination with heat (thermosonication), with pressure (Mano-snocation) with both (Manothermosonication). These combinations significantly increase the lethality of ultrasound making it possible not only to pasteurise but even to sterilise food products.

Pros

Among the advantages, as compared to other traditional novel food preservation technologies, are these ultrasound-based processes:

-Capable of inactivating spores

-Capable of inactivating enzymes

-Especially useful for thermo-sensitive food products

-Good alternative for the pasteurisation of low water activity liquid products

-Microbial inactivation by ultrasound is less affected by product characteristics than heat and most non-thermal technologies

Cons

The major limitations would be:

-Only for liquid products

-Large scale systems still unavailable (TRL 4-5)

-Impact on food quality and nutritional properties still to be fully elucidated.

| Title | Author(s) | Year | |

|---|---|---|---|

| Microbial inactivation by non-thermal technologies for food preservation | Guillermo Cebrián and Santiago Condón | 2017 | Go to publication |

| Decontamination efficiency of high power ultrasound in the fruit and vegetable industry, a review | Seda Ersus, Fulya Turantaş | 2013 | Go to publication |

| Ultrasound in the meat industry: General applications and decontamination efficiency | Fulya Turantaş, Gülden Başyiğit Kılıç and Birol Kılıç | 2014 | Go to publication |

| Comparative Resistance of Bacterial Foodborne Pathogens to Non-thermal Technologies for Food Preservation | Cebrián, G., Mañas, P. and Condón, S. | 2016 | Go to publication |

| Application of High-Power Ultrasound in the Food Industry | Leire Astráin-Redín, Salomé Ciudad-Hidalgo, Javier Raso, Santiago Condón, Guillermo Cebrián and Ignacio Álvarez | 2019 | Go to publication |