Find out what happens when pores are formed in the cells, and what is needed to perform PEF treatments on food products.

Definition and equipment

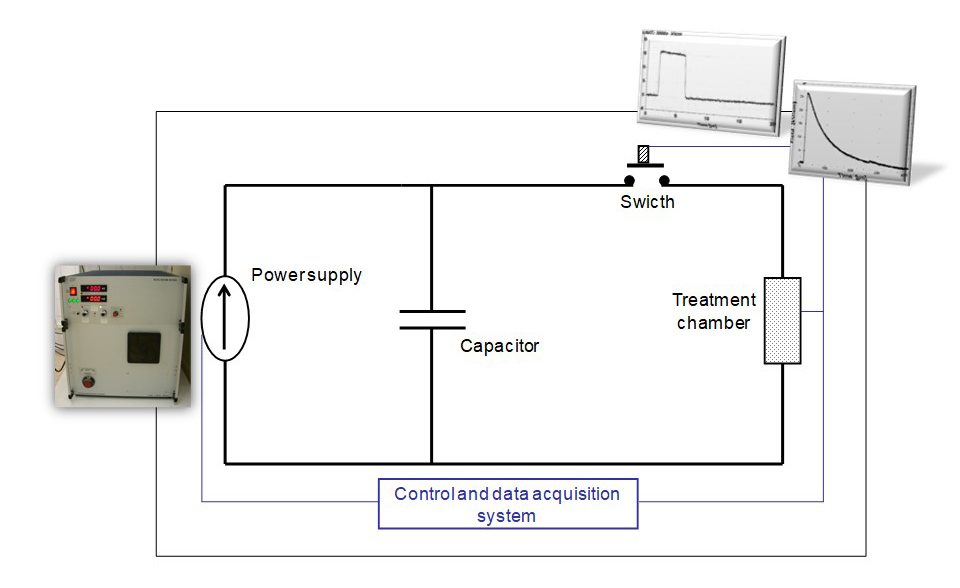

PEF technology consists of applying high electric fields (1-50 kV/cm) in short pulses (µs-ms) to a matrix located between two electrodes. A basic overview including the essential parts of a PEF treatment system is shown in the figure above.

Basically, it requires a pulse modulator and a treatment chamber to expose the food to the electric fields. The pulse modulator transforms the sinusoidal alternating current from the power line into pulses with sufficient peak voltage and pulse energy, which are delivered to the treatment chamber by means of a switch.

PEF treatments can be applied in batches and/or as continuous flow, and through the application of exponential decay, rectangular, and monopolar or bipolar pulses.

Mode of action

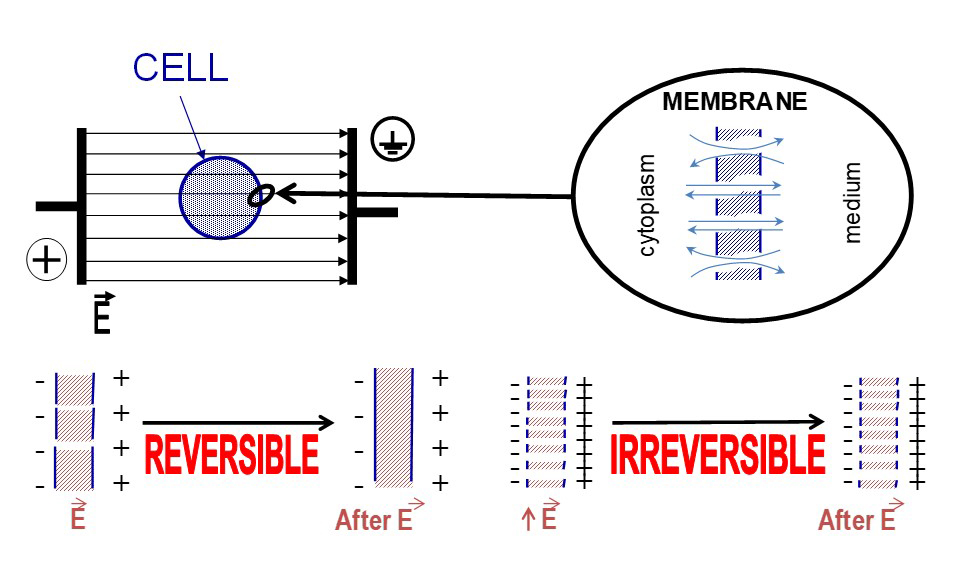

Exposure to external electrical fields leads to membrane permeabilisation (formation of pores) in microbial, plant or animal cells – a phenomenon called electroporation.

According to the most widely accepted theory, the formation of pores happens because, when an external electric field is applied, a high amount of free charges of opposite charge accumulate on each side of the biological membranes. Since these charges are opposites, they attract each other, and, once a critical electric field value or threshold is reached, the membrane is unable to withstand the compression forces, so pores are formed.

Treatment parameters

The most relevant treatment parameters in PEF processes are:

- Electric field strength (in kV/cm)

- Treatment time

- Pulse shape (exponential decay or rectangular; monopolar or bipolar)

- Pulse width

- Pulse frequency

- Specific energy

- Treatment temperature

For the disintegration of plant or animal cells, an electric field strength of 1kV/cm is typically required, whereas microbial inactivation occurs above the critical field strength of 15kV/cm. Similarly, the specific energy associated with treatments aiming to permeabilise animal or plant cells is usually much lower than that required in microbial inactivation processes.

Regarding treatment temperature, it should be noted that, although PEF technology emerged as a non-thermal technique for food preservation, the effect of PEF on biological membranes has been shown to notably increase with temperature. In addition, PEF can also be used for the volumetric heating of foods, which is one of its most recently explored applications.

Read also: PEF in the food industry

References:

Microbiological aspects related to the feasibility of PEF technology for food pasteurization. Saldaña, G.; Álvarez, I.; Condón, S.; Raso, J.

Applications of pulsed electric field treatments for the enhancement of mass transfer from vegetable tissue. Donsì F, Ferrari G, Pataro G.

Pulsed Electric Field-assisted extraction of valuable compounds from microorganisms. Martínez, JM, Delso, C, Álvarez, I, Raso, J.

Ohmic heating and moderate electric field processing. Sastry, S.

Perspective on Pulsed Electric Field Treatment in the Bio-based Industry. Buchmann L and Mathys A

Mechanisms of cell membrane electropermeabilization: a minireview of our present (lack of?) knowledge. Teissie, J., Golzio, M., and Rols, M. P.

Pulsed electric fields treatment in food technology: Challenges and opportunities. Jaeger, H., and Knorr, D

Handbook of Electroporation, ed D. Miklavčič (Cham: Springer International Publishing AG), 2657–2680.

Application of pulsed electric field in the production of juice and extraction of bioactive compounds from blueberry fruits and their by-products. Bobinaite, R., Pataro, G., Lamanauskas, N., Šatkauskas, S., Viškelis, P., and Ferrari, G.