How ultrasound works in food processing

Find out what happens when ultrasonic waves causes cavitation, and what equipment is needed to perform ultrasound treatment of food products.

What is ultrasound?

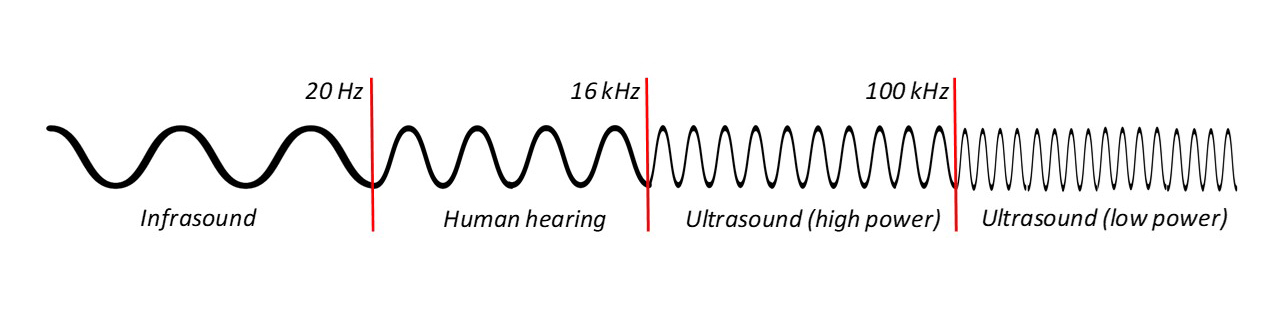

Ultrasonic technology consists of the application of sound waves with frequency over the threshold of human hearing (>16 kHz). Depending on its frequency and intensity, the ultrasound can be further divided into low frequency (20–100 kHz) high-power (>1 W/cm2) ultrasound and high-frequency (>100 kHz) low-power (<1 W/cm2) ultrasound.

Low-power ultrasound is applied for noninvasive and nondestructive analyses, and it is mainly used in other areas such as medicine and cosmetics. In the food industry, this type of ultrasonic waves is basically used for process and quality control (e.g., fluid flow and container filling control, location of foreign bodies, or evaluation of the homogenisation and/or emulsification efficiency).

In contrast, high-power ultrasound is able to produce changes in the material or process to which they are applied, and it is used in a large variety of processes in the food industry (e.g., surface cleaning and decontamination, microbial and enzymatic inactivation, degassing, defoaming, and component extraction, among others).

Approaches and equipment

Ultrasonic sound waves can propagate through air, liquid, and solid media, but, at the same time, the medium of propagation highly conditions its effects. Applying ultrasound in a liquid medium is the most common scenario in the food industry.

Cavitation is the main phenomenon responsible for ultrasound effects when applied to a liquid. Basically, cavitation occurs when the microbubbles present in the liquid increase in size as a result of the cycles of high and low pressure generated by the ultrasonic waves until they become unstable and collapse. This implosion leads to the generation of shock waves and microjets that can lead, depending on the intensity of the treatment applied, to the breakage of cells (useful for the extraction of compounds from vegetable cells, for instance) or to the release of cells/particles (for instance, for surface cleaning).

Depending on the treatment parameters, ultrasound can also induce the generation of free radicals. Therefore, this should be considered when designing ultrasoinc treatements.

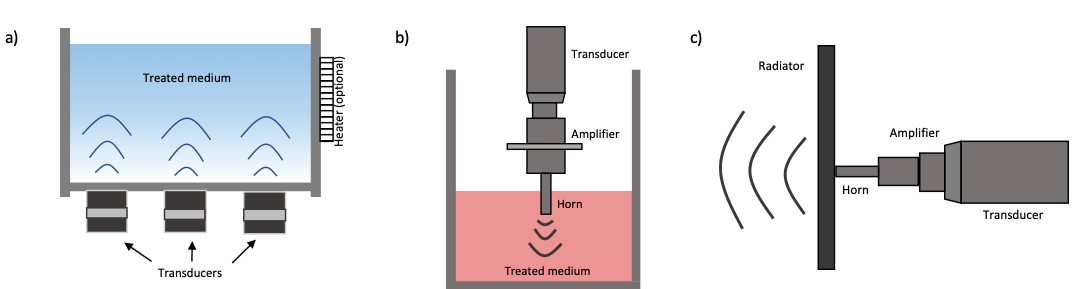

Two types of equipment can be used for applying US through liquid media (Figure 2): ultrasound water baths (less powerful, but cheaper and easier to be scaled up) and probes or horns (more powerful but also more expensive and difficult to apply on an industrial scale).

On the other hand, applying ultrasound to gases is complex and limited by different causes, including the power loss that occurs when doing so but, as will be discussed below, it has very interesting applications such as defoaming and assisted drying. For this particular application, airborne probes have to be used.

Finally, ultrasound can also be directly applied to solid media, which might help to improve heating or colling rates, for instance.